Mid-Volume PCB Assembly plays a critical role for companies that operate between prototyping and full-scale mass production. It is designed for businesses that need consistent output, stable quality, and controlled costs without committing to extremely high production quantities. Typically, mid-volume production supports growing products that have passed validation stages and are ready for market expansion. This stage requires tighter process control, repeatable quality, and supply chain stability, making Mid-Volume PCB Assembly an essential manufacturing strategy for technology-driven industries.

On this page

- Why Mid-Volume PCB Assembly Is Strategically Important

- Key Characteristics of Mid-Volume PCB Assembly

- Production Flexibility Without Sacrificing Quality

- Cost Efficiency at Controlled Volumes

- Industries That Rely on Mid-Volume PCB Assembly

- Process Control in Mid-Volume PCB Assembly

- Component Management and Supply Chain Stability

- Quality Assurance in Mid-Volume PCB Assembly

- Reliability and Lifecycle Performance

- Scaling From Mid-Volume to High-Volume Production

- Conclusion

Why Mid-Volume PCB Assembly Is Strategically Important

Mid-Volume PCB Assembly fills the gap between low-volume flexibility and high-volume efficiency. At this stage, manufacturers must deliver uniform performance across hundreds or thousands of assemblies while still allowing engineering refinements. Many companies choose mid-volume production when product demand is increasing but not yet predictable enough for full automation at mass-production levels. This approach enables controlled scaling, better cost forecasting, and faster response to market changes.

Key Characteristics of Mid-Volume PCB Assembly

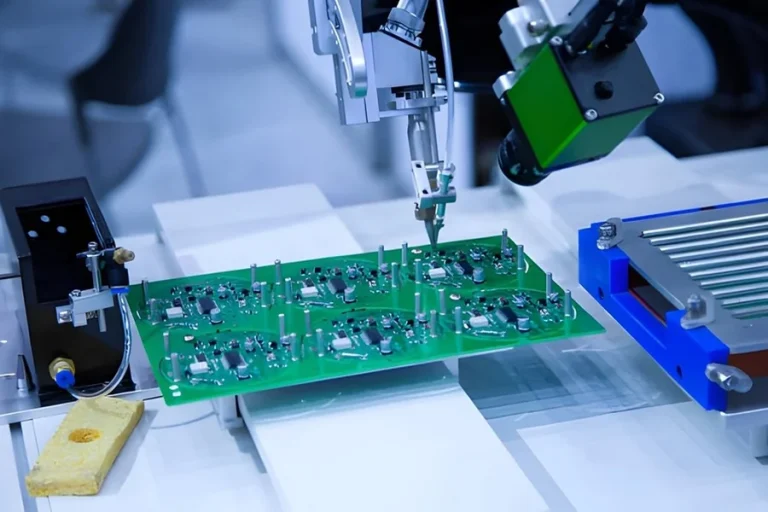

Mid-Volume PCB Assembly is defined by stable processes, semi-automated production lines, and consistent quality assurance. Unlike prototypes, which focus on design verification, mid-volume builds emphasize repeatability and reliability. Assemblies are produced using validated bills of materials, established test procedures, and standardized work instructions. This consistency ensures that each unit performs identically, which is essential for products entering commercial distribution.

Production Flexibility Without Sacrificing Quality

One of the most valuable aspects of Mid-Volume PCB Assembly is its flexibility. Manufacturers can accommodate design updates, component substitutions, and process optimizations without the complexity of reconfiguring high-volume production lines. This flexibility allows companies to refine their products based on customer feedback or regulatory requirements while maintaining strict quality standards.

Cost Efficiency at Controlled Volumes

Mid-Volume PCB Assembly offers a balanced cost structure. While it does not achieve the lowest unit cost seen in mass production, it significantly reduces expenses compared to low-volume builds. Component sourcing becomes more economical, setup costs are amortized over larger quantities, and process efficiencies lower overall production costs. This makes mid-volume manufacturing financially viable for companies preparing for global expansion.

Industries That Rely on Mid-Volume PCB Assembly

Mid-Volume PCB Assembly is widely used across industries that demand both performance and reliability. Industrial automation systems depend on mid-volume production to ensure long-term stability in controllers and sensors. Medical device manufacturers use mid-volume assembly to meet regulatory requirements while scaling production responsibly. Automotive electronics, including infotainment systems and control modules, benefit from mid-volume builds that support gradual ramp-up. Telecommunications, aerospace subsystems, and consumer electronics also rely heavily on this production model.

Process Control in Mid-Volume PCB Assembly

Process control is a defining factor in successful Mid-Volume PCB Assembly. Each step, from solder paste printing to component placement and reflow soldering, must be optimized for consistency. Statistical process control is often applied to monitor performance trends and detect variations early. Functional testing, in-circuit testing, and visual inspection are integrated to ensure that every assembly meets predefined specifications. This disciplined approach minimizes defects and supports long-term product reliability.

Component Management and Supply Chain Stability

Mid-Volume PCB Assembly requires careful component planning. At this stage, manufacturers must ensure long-term availability of parts while maintaining cost control. Approved vendor lists, alternate components, and inventory buffering strategies are commonly used to reduce supply chain risks. Stable sourcing is particularly important when products are scheduled for extended production cycles.

Quality Assurance in Mid-Volume PCB Assembly

Quality assurance becomes more structured during Mid-Volume PCB Assembly. Unlike prototype builds, where issues are expected and corrected frequently, mid-volume production aims for first-pass success. Inspection standards, testing coverage, and documentation are formalized to ensure compliance with industry standards such as IPC. Traceability is also implemented, allowing manufacturers to track materials, processes, and test results for every production batch.

Reliability and Lifecycle Performance

Products manufactured through Mid-Volume PCB Assembly are often deployed in real-world environments for extended periods. This makes reliability testing essential. Thermal cycling, vibration testing, and functional stress testing are commonly applied to validate long-term performance. These measures help manufacturers identify potential failure modes before scaling to higher volumes.

Scaling From Mid-Volume to High-Volume Production

Mid-Volume PCB Assembly acts as a bridge to high-volume manufacturing. Data collected during this phase helps manufacturers refine processes, improve yields, and optimize production flow. By analyzing defect trends, cycle times, and cost structures, companies can make informed decisions about when and how to scale. This reduces risk and ensures a smoother transition to mass production when demand increases.

Choosing the Right Partner for Mid-Volume PCB Assembly

Selecting the right manufacturing partner is crucial for successful Mid-Volume PCB Assembly. The ideal partner should offer strong engineering support, flexible production capabilities, and robust quality systems. Experience with diverse product types and industries ensures that assembly challenges are addressed proactively. Transparent communication and scalable infrastructure further support long-term growth.

Conclusion

Mid-Volume PCB Assembly provides the perfect balance between flexibility, cost efficiency, and production stability for companies ready to scale their products responsibly. It supports consistent quality, controlled growth, and reliable performance across a wide range of applications. For businesses seeking seamless integration of fabrication, assembly, testing, and logistics, partnering with a china one-stop pcb assembly service ensures efficient production, dependable quality, and a clear path from mid-volume manufacturing to full-scale success.